The Basics of Airplane Propellers and How They Work

25 March 2022 | Updated on February 05, 2024

Ever since the Wright brothers first took to the skies in a heavier-than-air powered flying machine, people have been fascinated by the power of flight. One of the key components of any successful aircraft is its propulsion system, and the heart of that system is the propeller (except for gliders of course). Propellers come in a variety of shapes, sizes, materials and types, each with its own unique characteristics, advantages and disadvantages.

Although the aerodynamical concept of airplane propellers can become quite complex, we will try to explain the basics of how they work, and the different types that you may come across. We will also look touch upon a few important basics associated with aircraft props.

How do Airplane Propellers Work?

Before we get into the different types of airplane propellers, it’s important to understand what they are and what they do.

In short, airplane propellers are rotating wing-like blades that create thrust by propelling a plane through the air. Two or more blades spin around a central hub, which is attached to the engine shaft.

The principle behind how a propeller works is relatively simple. The fundamentals of airplane propellers are mostly based on Sir Isaac Newton’s Third Law:

“For every action, there is an equal and opposite reaction.”

In order for a propeller to thrust an airplane forward, the blades must first push air backward (the action). This causes an opposite force that propels the plane forward (the reaction).

The greater the amount of air that is pushed behind the prop, the more thrust or forward propulsion they produce.

Propeller Basics

As just mentioned, propellers are one of the most aerodynamically complex concepts in aviation. To understand better how they work, it’s important to look at some of the basic concepts related to airplane props.

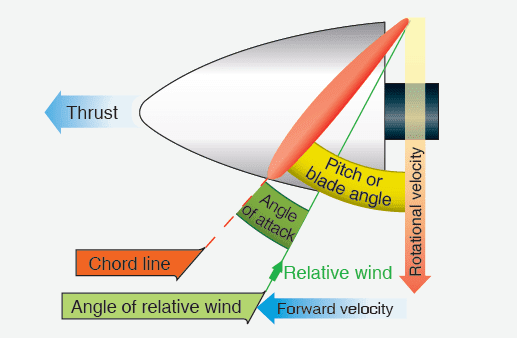

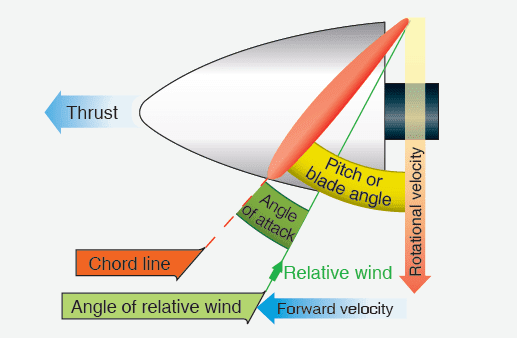

Chord Line

The chord line is an imaginary line drawn through the center of the blade from its leading edge (at the root or hub) to its trailing edge (the tip). The leading edge, as in a wing, is the thickest edge of the blade that meets the air as the propeller spins.

Blade Angle

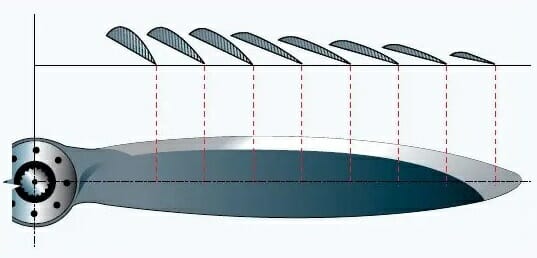

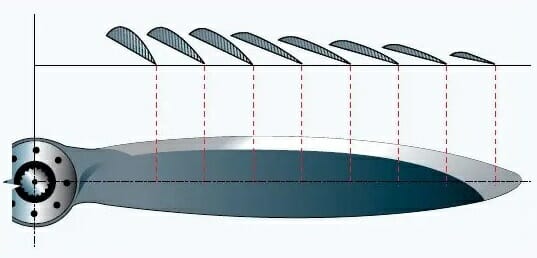

A propeller’s blades are not straight; rather, they are angled like a screw.

The blade angle is the angle in degrees between the chord line and the plane of rotation and is measured at a specific point along the length of the blade.

Why is an airplane propeller twisted?

The reason a propeller’s design is “twisted” is that the outer portions of its blades, like all objects that turn about a central point, move faster than the inner areas. When the blades had a constant geometric pitch all the way along their lengths, portions near the hub would have a negative Angle of Attacks and the propeller tips would stall at cruising speeds.

Pitch

The pitch is defined as “the distance a propeller would move in one revolution if it were moving through a soft solid, like a screw through wood“.

The pitch of a propeller blade changes as it moves from the hub out to the tip. The blade angle is usually the steepest or shortest at the root and decreases towards the tip.

This is because a propeller’s blades are shaped somewhat like an airfoil, which allows them to “bite” into the airstream and produce more thrust.

The pitch is steepest (shortest) at the central hub and shallowest at the outer propeller tip.

Although often used interchangeably with blade angle, both are different concepts. While blade angle is a measured physical angle expressed in degrees, the pitch, on the other hand, is the distance in inches that a propeller section will advance in one revolution.

In general, though, an increase or decrease in one is usually associated with a similar increase or decrease in the other.

Angle Of Attack

Angle of Attack is a common concept in aviation and aerodynamics.

It’s the angle measured between the chord line of a wing and the airflow going around it. When talking about airplane propellers, the angle of attack is the angle at which the airflow hits the propeller blade(s).

As with wings, increasing the angle of attack to a greater degree generates more lift and induced drag up until the point of a stall.

As mentioned above, the twist of a propeller blade is designed to keep the Angle of Attack along the blade length more constant.

Recommended

How Fast do Airplanes Fly?

How Many Blades do Airplane Propellers Have?

Most airplane propellers have between two and six blades. The number of blades on a prop will affect the amount of thrust it produces, as well as how efficiently it moves through the air.

The amount of thrust generated by a propeller is determined by the number and angle of its blades, as well as the size and form, and the engine’s power.

The number of propeller blades is again determined by the type of aircraft and its flight performance requirements, as well as engine power.

The propeller’s disc area should increase together with the engine power. However, this growth is limited by the blade tips’ speed. Once the flow speed at this point becomes supersonic, it causes the drag on that section of the blade to rise without a corresponding increase in thrust.

To counter this problem, the next best alternative is to raise the propeller’s solidity ratio, also known as the activity ratio. This may be achieved by either increasing blade length, or adding additional propeller blades.

However, it’s important to note that in fact, more blades are actually bad for efficiency. The ideal airplane propeller has only one blade. Depending on the specific propeller design, every additional blade may create disturbances, which will affect the flow on other blades.

Efficiency generally runs inverse to the number of blades. The fewer blades you need for lift (or thrust) generation, the better.

However, if sufficient engine power is available, adding more blades is the most effective way to convert engine power into thrust.

Also, propellers need to be balanced, which offers quite a few challenges when using a single-bladed propeller. The aerodynamics are also quite a bit more complex than our explanation here. If you like to learn more about this concept, we recommend checking out this interesting conversation on Aviation Stack Exchange and the other articles mentioned in the discussion.

2-Bladed Airplane Propellers

Because of the practical complexity of single blades, the most common sight on general aviation aircraft is a two-bladed propeller.

The advantages of having two blades are that the propeller is easier to balance, and the aerodynamic design is not as complex as it would be for a single-blade prop.

Another advantage of two-bladed props is that they can be made from lighter and less expensive materials, which reduces the overall weight of manufacturing cost of the propeller.

They are, however, limited in the amount of air they can displace, and thus, the amount of forward thrust. Hence why they’re not typically seen on larger or more powerful aircraft.

4-Bladed Airplane Propellers

Four-bladed propellers are also popular on small planes, usually ones with higher engine power. Although considerably more expensive, they offer several advantages over two-bladed propellers.

Four-bladed props produce more thrust than an equivalent two-bladed model, which is helpful when flying a performant airplane. Depending on the specific prop characteristics, they may also offer smoother operation and reduced vibration, which makes for a more comfortable flight.

6-Bladed Airplane Propellers

Six-bladed propellers are typically only used on aircraft with very high engine power, such as large commercial aircraft or other powerful turboprops, like military planes or single-engines like the TBM-900.

What are Airplane Propellers Made Of?

Propellers are made from a variety of materials, depending on the application. For instance, small general aviation aircraft propellers are typically made out of aluminum or wood, while larger turboprops may use composites and most jet engine blades are made out of expensive titanium.

Wooden Airplane Propellers

For many decades, the majority of propellers were made out of wood. Even now, a lot of traditional and vintage aircraft use wooden propellers.

Wood is a relatively cheap and easy to work with material, which makes it ideal for small general aviation aircraft. It’s also a fairly light material, which helps reduce the overall weight of the airplane.

Wooden propellers are constructed by layering strips of wood, usually yellow birch, black cherry, sugar maple or black walnut, and bonding them together with glue. The propeller is then shaped and balanced before being coated with a layer of sealant to protect it from the elements.

As aircraft engine power increased, and the need for more efficient propellers grew, wooden propellers were gradually replaced by aluminum propellers.

Aluminium Airplane Propellers

Aluminum alloy propeller blades were introduced and quickly became the standard for general aviation aircraft.

Aluminum is a strong yet lightweight material, which makes it ideal for propellers. It’s also relatively easy to repair, which is another major advantage in general aviation.

Composite Airplane Propellers

Nowadays, a lot of the higher-end general aviation and complex aircraft use composite materials for their propellers.

Composite propellers offer several advantages over traditional aluminum propellers. They’re typically lighter, quieter, more efficient and they create fewer vibrations. Composite blades are also even easier to repair compared to other types of materials.

The 5 Major Types of Aircraft Propellers

Now, let’s finally take a look at the different types of airplane propellers that you might encounter.

1. Fixed-Pitch Propellers

Fixed-pitch propellers are the most basic type of propeller. As the name implies, they have a fixed pitch determined during manufacturing, which cannot be changed on the ground or in-flight.

The fixed pitch of these types of propellers was determined to be the optimal pitch for specific circumstances. This means that when circumstances and conditions change, the pre-set pitch for this propeller may not stay optimal.

This type of propeller is mostly found on single-engine general aviation aircraft, as they are the least complex and most-inexpensive option. Single-engine GA airplanes usually fly at lower altitudes and at lower relatively constant airspeeds, so a variable pitch is usually not required.

2. Variable Pitch Propellers

As the name implies, variable pitch propellers don’t have a fixed pitch and offer the pilot the ability to change the propeller pitch while in-flight, which allows for optimal efficiency under different conditions.

The vast majority of general aviation twin-engine and some more performant single-engine aircraft use variable pitch propellers. This is because they usually fly at changing speeds and altitudes, requiring a different propeller pitch setting for different flight conditions.

When it comes to variable pitch propellers, we can generally differentiate between 2 types: constant speed propellers and controllable speed propellers.

Constant speed props are designed with a variable blade pitch, which is automatically adjusted to be optimal in various flight conditions and performance requirements. The pilot just sets the desired engine RPM, and the blade pitch is controlled automatically so that the rotational speed remains constant. Hence the term “constant” speed propeller. The automatic adjustments are performed by the device called the propeller governer or constant speed unit (CSU).

Controllable speed propellers, on the other hand, offer the same flexibility, but they allow the pilot to manually set the desired pitch. This is done with the recognizable blue-colored lever, usually located between the throttle and mixture lever in piston-powered aircraft, or next to the throttle lever in turboprop or diesel-powered piston aircraft.

Although not officially a different type of propeller, you may also come across the term Reversible propeller. These are variable pitch propellers where the pitch can be set to negative values. This creates reverse thrust for braking or taxiing backward without the need to change the direction of shaft revolution.

This type of propeller is often found on large military turboprop transport aircraft, like the C-130 Hercules.

3. Ground-Adjustable Propellers

Some smaller aircraft, like ultralight and microlights, are equipped with so-called ground-adjustable propellers. These are not considered variable pitch propellers, but they offer the possibility to adjust the propeller’s pitch on the ground in-between flights.

Because of the added cost and little extra convenience or operational performance gains, this type of propeller is not often found anymore.

Airplane Propellers as Decoration

Since aircraft propellers are one of the most iconic symbols of aviation, it is no surprise that they make for great decoration.

Whether you’re looking for the perfect decoration to spruce up your living room or want a fun conversation starter in your entryway, decorative aircraft propellers are just what you need. In fact, aircraft propellers are so popular as home decorating pieces because they are not only aesthetically pleasing but also serve to remind us all how incredible flight technology has become over time.

If you’re looking for the perfect finishing touch on your aviation-themed home then check out our other article with 12 stunning decorative aircraft propellers:

Because nothing symbolizes aviation history more simply and evocatively than propellers.

Conclusion

We hope the above article has given you an insight into the basics of aircraft propellers, propeller materials, sizes, and of course the different types you may come across at airports today.

Want to learn more about the different aerodynamical concepts related to airplanes?

Check out Rod Machado's extensive e-learning course on aerodynamics. It’s an excellent course for anyone pursuing a sport, recreational or private pilot certificate. It’s also an excellent course to help flight instructor applicants develop their teaching strategy and style.