The Difference Between Turbojet and Turbofan Engines Explained

17 October 2022 | Updated on February 05, 2024

Jet engines revolutionized the aviation industry and shrunk the world, changing how we travel, do business, and relax.

Jet engines come in various types. When reading about your favorite jet planes online or in magazines. you may have noticed that jet-powered airplanes have either turbojet or turbofan jet engines. But what exactly is the difference between the two?

Turbojet and turbofan engines derive thrust through the ejection of hot gasses created by compressed air burning at high temperatures inside combustion chambers. They share similar (but limited) operational and design features, including an identical low-pressure front section design and the ability to operate at the same altitude. And both engines burn the same fuel type.

However, the differences between turbojet and turbofan engines extend beyond what you think you know. Let’s take a look at the difference between turbojet vs. turbofan engines, their operation, and other exciting details!

Turbojet Engines

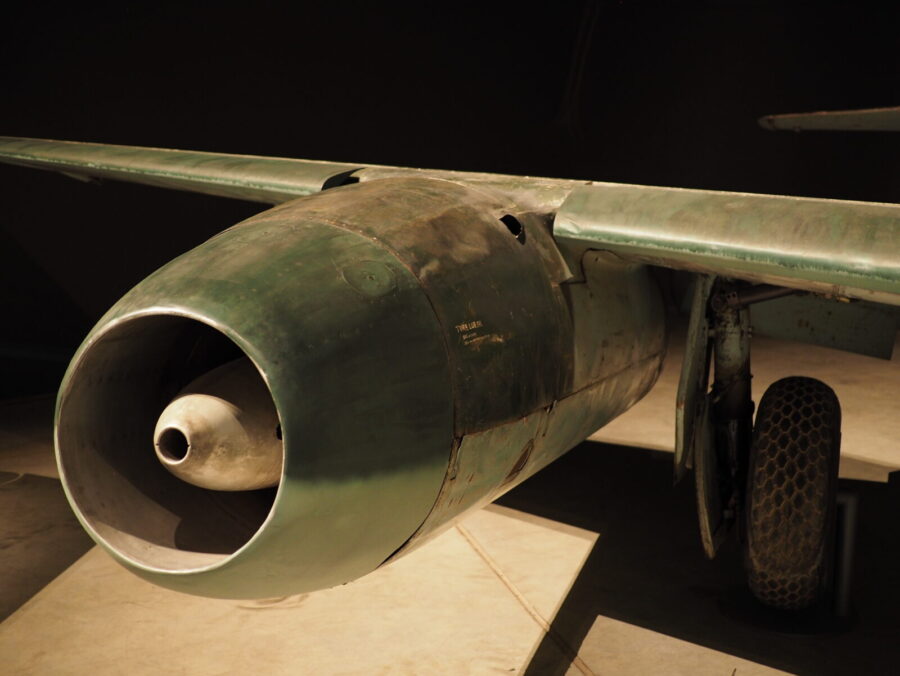

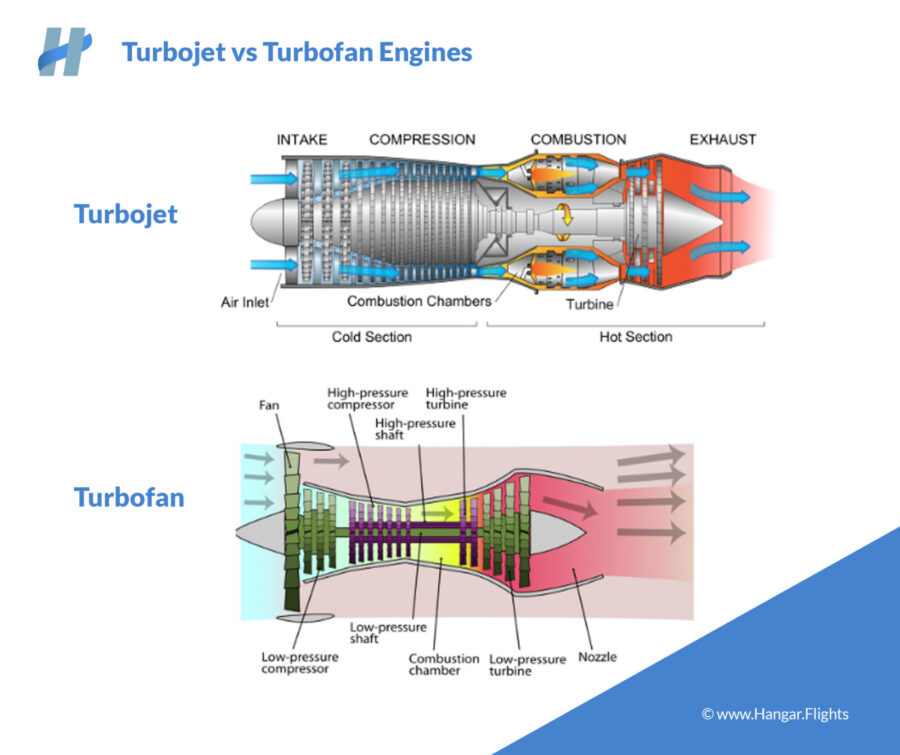

A turbojet is an air-breathing aircraft engine consisting of an intake fan, gas turbine, and propelling nozzle. Unlike reciprocating piston engines, turbojets use hot exhaust gasses from their gas turbine to create thrust.

However, Frenchman Maxime Guillaume first patented the turbojet design in 1921. Two engineers working separately in England and Germany during the 1930s developed the turbojet concept. In 1937, English engineer Sir Frank Whittle tested the first turbojet engine prototype, but the British government halted its development because of a lack of funds and disinterest. However, German engineer Hans Von Ohain’s turbojet project became the first production turbojet engine design and made its first flight in the HE-178 airplane on 27 August 1937.

Turbojet engines significantly influenced the design of early commercial and military aircraft. They enabled us to break the sound barrier setting new flight records and reshaping the commercial aviation industry.

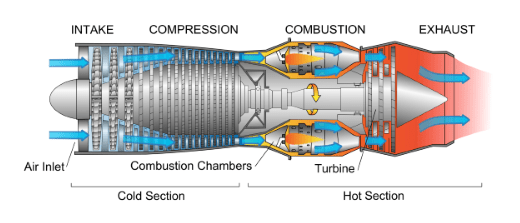

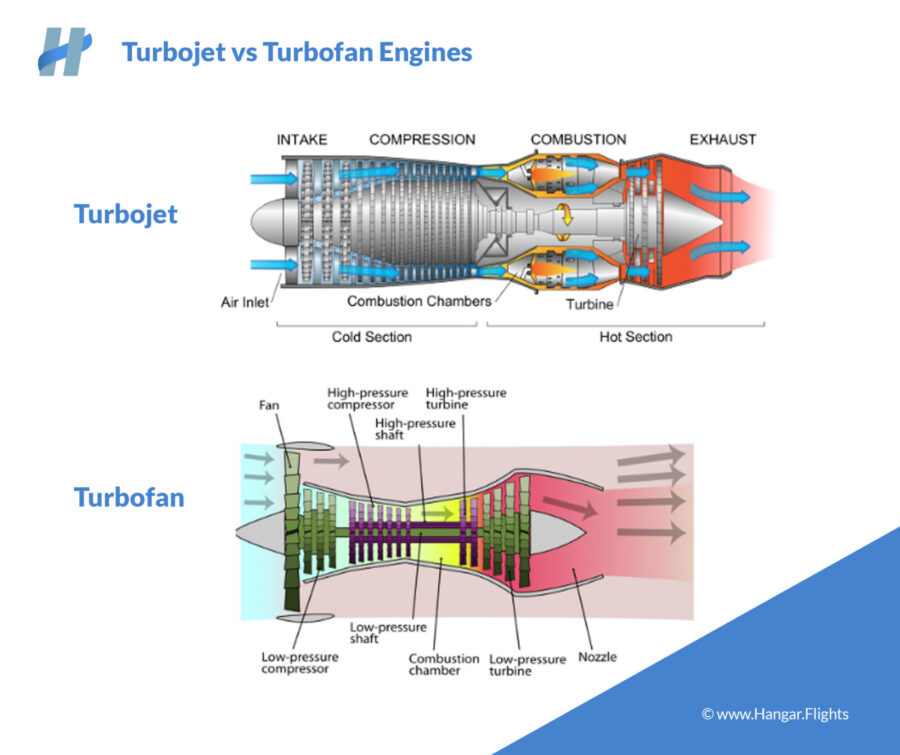

A turbojet engine consists of fewer movable parts than a turbofan engine, consisting of an inlet, burner, compressor, turbine, combustion chamber, and a rear-facing nozzle.

Types of turbojet engines

There exist two main variations of the turbojet engine, namely,

Centrifugal-flow turbojet engine

Early production turbojets had the centrifugal compressor resembling an automobile turbocharger unit, and it worked by turning the flow of air perpendicular to the axis of the impeller’s rotation. Centrifugal compressors were a standard feature on early jet engines, and they continue to be a common feature on modern turboshaft engines. A primary advantage of the centrifugal compressor is its effective single-stage operation, resulting in a non-complicated engine design and manufacture.

Axial-flow turbojet engine

It is a turbojet engine using an axial compressor in which the airflow is parallel to the shaft’s rotation axis. It is a standard feature on modern jet engines, and it was developed to coerce extra performance out of the turbojet engine. You can quickly identify an axial-flow turbojet by its longer engine pod with a smaller cross-sectional area which minimizes drag. The advantages of an axial compressor include higher airflow efficiency and increased thrust.

How a turbojet engine works

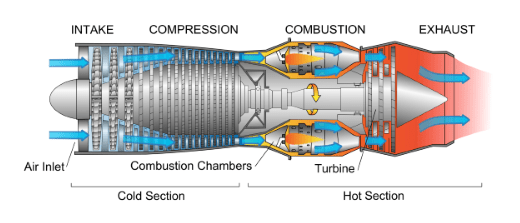

A turbojet is a gas turbine that operates on the Brayton Cycle by extracting energy from the heat provided through constant pressure. A gas turbine (turbojet) typically consists of three stages, and here is your chance to learn how it works.

- Compression stage – incoming cold air is compressed to high pressures as it passes through the alternating moving and stationary compressors into the combustion chamber.

- Combustion stage – fuel is added to the compressed air inside the combustion chamber. The air and fuel mixture ignites in continuous explosive combustion of 1200o C and 1000 kPa generating enough force to run the engine by spinning the turbine blades and driveshaft.

- Turbine section – is where the good stuff happens. The turbine extracts the energy released from the combustion chamber and expands it through the nozzles at high pressure, and the force of the hot exhaust gasses provides thrust.

Benefits of a turbojet engine

When we compare turbojet vs. turbofan engines, it is easy to knock the turbojet engine for its shortcomings. But let us not forget that we have more efficient alternatives. But let’s not forget the numerous benefits of turbojet engines which we shall list below.

- A turbojet engine’s simple and lightweight construction provides a high power-to-weight ratio.

- A turbojet engine has a high climb rate.

- Turbojet engines comprise fewer mating components that generate excessive wear.

- A turbojet engine has lower maintenance costs than a turbofan engine.

- Turbojet engines are designed for high-speed operations at very high temperatures.

- Turbojet engines can use low-grade fuel without fear of engine damage.

- It consists of zero unbalanced forces ensuring a vibration-free operation.

Turbofan Engines

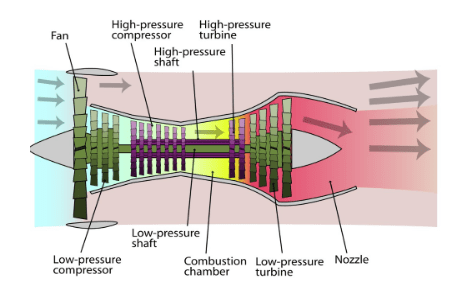

A turbofan engine is the standard air-breathing engine on modern jet aircraft. It generates thrust force by combining two major parts; a gas turbine and a ducted fan. Turbofan engines evolved from the turbojet design concept, But its driveshaft, in addition to driving the compressor, also powers the large ducted fan that produces a secondary thrust mass by bypassing air away from the core engine components.

Early turbofan engine designs debuted in 1943, but it wasn’t until the early 1960s that the first production examples were fitted to the Lockheed C-5 Galaxy military transport aircraft. The massive fans you see on the front of the turbofan engine are its only visual components. They also offer greater efficiency by providing a higher ratio of mass engine flow compared to fuel burn.

The main components of a turbofan engine include the air intake, fan, compressor, combustion chamber, turbine with a compressor driving shaft and fan, and exhaust nozzle.

How A Turbofan Engine Works

As implied in the name, the ducted fan assembly of the turbofan engine plays a role in generating thrust. Turbofan engines work by using the air passing through the fan into the core of the engine and the air bypassing the engine to provide thrust for the aircraft.

In the first stage, the engine inlet sucks incoming air and passes it through the fan into the core compressors, pressuring the air before sending it into the combustion chamber, which completes the second stage.

The third stage begins inside the combustion chamber, where burners mix fuel with the pressurized air creating high-pressure combustion. The energy derived from the combustion goes into the high-pressure turbines (fourth stage) and out through the core nozzle (fifth stage).

Some of the air passing through the fan during the first stage goes into the nacelle bypassing the engine. It is expelled through the cold nozzle at high velocities without undergoing pressurization or combustion.

Since a turbofan engine derives thrust from both hot air generated by the core and cold air from the fan, the ratio of the air going around the engine to the air passing through the core is known as the bypass ratio (BPR).

Types Of Turbofan Engines

You may be interested to learn that not all turbofan engines are created similarly. Turbofans are rated according to their BPR, which helps to determine their fuel efficiency versus thrust. Both civilian and military jet aircraft use different variations of turbofan engines. So, what are the types of turbofan engines and their application?

- Low-bypass turbofans – are turbofan engines generating more jet thrust relative to fan thrust with a bypass ratio of 2:1 or lesser for aircraft with speeds up to Mach 2. Low-bypass turbofans with afterburners are common on military aircraft like fighter jets because the concept combines the high speeds of a turbojet with the advantages of a turbofan engine. It allows fighter jets to achieve optimum fuel efficiency during cruising but provides sufficient thrust required during dogfights.

- High-bypass turbofans – high-bypass turbofan engines generate more fan thrust relative to jet thrust with a bypass ratio of over 2:1. High-bypass turbofan engines on new-generation commercial airliners can have bypass ratios of up to 12:1 and share similar fuel efficiency with a turboprop engine because the amount of airflow diverted through the cold path around the engine core ranges between 30% – 80% of the overall air intake. The most common application of high-bypass turbofan engines is on commercial airliners.

Benefits of a turbofan engine

Turbofan engines are the most modern jet engine types in production, offering a high degree of flexibility and performance for aircraft of all sizes. Here are some of the benefits of a turbofan engine.

- Turbofans are cheaper to operate.

- A turbofan engine has high fuel efficiency.

- Turbofans are quieter than other jet engine types.

- They produce fewer emissions.

Turbojet vs. Turbofan engine differences

I know most readers can’t wait to get to this section. Still, as you read through the article, you’d have guessed most of the differences between turbojet vs. turbofan engines. So, why don’t we list and compare the differences between turbojet vs. turbofan engines?

| Turbojet Engine | Turbofan Engine |

|---|---|

| It is the first generation of jet engines fitted to military and civilian aircraft. | It was developed from the turbojet engine for better efficiency. |

| It is optimized for very high supersonic flight operations but is not efficient at low subsonic speeds. | It is efficient at both high-speed subsonic speeds and transonic flight speeds. |

| It is extremely noisy at both high and low speeds. | It produces much less noise and is much quieter than a turbojet. |

| It has poor fuel efficiency compared to a turbofan engine. | It has an excellent fuel efficiency |

| The engine has a thinner and more aerodynamic shape when viewed from the outside. It is longer and narrower than a turbofan. | Turbofans are wider, with a shorter and stubby appearance when you view them from the outside. |

| Produces thrust purely by exhaust released from the gas turbine. | Produces thrust by a combination of exhaust from the gas turbine and bypass flow. |

| Its main application is on military jets. | It is commonly used on commercial airliners. |

| The turbine shaft drives a compressor. | The turbine drive shaft drives the compressors and a large ducted fan. |

| Does not have a fan. | Has a large fan. |

Turbojet vs. Turbofan Engine Aircraft List

As you know, the production of turbojet and turbofan engines has been for over fifty years, with numerous examples on commercial and military aircraft. Although the use of turbojets has declined in favor of turbofan engines during recent decades, it still powers several aircraft around the globe.

Turbojet Aircraft List

| Aircraft With Turbojet Engine | Aircraft Role |

|---|---|

| Aerospatiale/BAC Concorde | Supersonic Passenger Airliner |

| Airbus A310 | Passenger Airliner |

| Avro Vulcan | Long Range Bomber |

| Boeing 727 | Passenger Airliner |

| Convair B-36 Pacemaker | Long Range Bomber |

| Dassault Mirage F1 | Multirole Fighter Jet |

| Douglas A-4 Skyhawk | Multirole Fighter Jet |

| Douglas DC-8 | Passenger Airliner |

| Messerschmitt Me 262 | Fighter Aircraft |

| Mikoyan-Gurevich MiG-25 Foxbat | Fighter Jet |

| North American F-86 Saber | Fighter Jet |

| Tupolev Tu-144 | Supersonic Passenger Airliner |

Turbofan Engine Aircraft List

| Aircraft With Turbofan Engine | Aircraft Role |

|---|---|

| Airbus A-300 | WIdebody Passenger Jet |

| Airbus A300-600 Beluga | Heavy Lift Transport/Freighter |

| Airbus A320 | Narrowbody Airliner |

| Airbus A380 | Widebody Airliner |

| Antonov An-225 Mriya | Strategic Heavy Lift Transport |

| McDonnell Douglas F-15 Eagle | Fighter Jet |

| Boeing 737 | Narrowbody Passenger Airliner |

| Boeing 747 | Widebody Passenger Airliner |

| Boeing 777/787 | Widebody Passenger Airliner |

| Mikoyan-Gurevich MiG-29 Fulcrum | Fighter Jet |

| Northrop Grumman B-2 Spirit | Stealth Heavy Bomber |

| Vickers VC-10 | Narrowbody Passenger Airliner |

Are turbofans more powerful than turbojets?

It depends on who you are asking. Most military applications favor turbojet engines for efficiency at high altitudes and high-supersonic speed operations. Turbojet engines on military aircraft have afterburners providing extra thrust to achieve supersonic speeds.

Turbofan engine designs have better efficiency and generate more thrust ratio per weight, making them more suitable for both high or low-speed operations at high or low altitudes than turbojet engines.

Conclusion

Today, people consider the turbojet engine an obsolete technology. But let us all take a moment to appreciate the unusual propulsion concept that changed the world – and our lives forever. Turbofans will continue to surpass the turbojet engine in power delivery and efficiency because it is an advanced version of the former. And turbofans will keep improving because of continuous development, unlike the turbojet engine, which is essentially retired.